Oil and grease sensor systems

Continuous monitoring of the oil condition allows you to detect deviations and potential problems in your transformer, hydraulic systems, aluminum rolling mills and large gearboxes at an early stage (typical problems in wind turbine gearboxes include bearing damage due to overstressing and fatigue). This allows for proactive maintenance that can reduce component failure and thus reduce costly downtime. Continuous monitoring allows decisions to be made to optimize oil changes, reducing maintenance costs and environmental impact.

Continuously monitor your high voltage transformers with our OilQSens OQ 3000 sensor system to minimize the probability of failure for the two most common reasons and thus ensure higher operational reliability:

1. insulating oil function: the insulating fluid of high-voltage transformers can oxidize or become contaminated over time, leading to a reduction in their insulating properties.

2. aging: older transformers have a higher risk of failure due to wear, aging and deterioration, and transformer action malfunction may occur.

It is therefore important to regularly maintain and monitor the transformer online to detect potential problems early and minimize the risk of failure. With our OilQSens OQ 3000 you are always aware of the current oil condition via the continuous online determination of the loss factor tan delta.

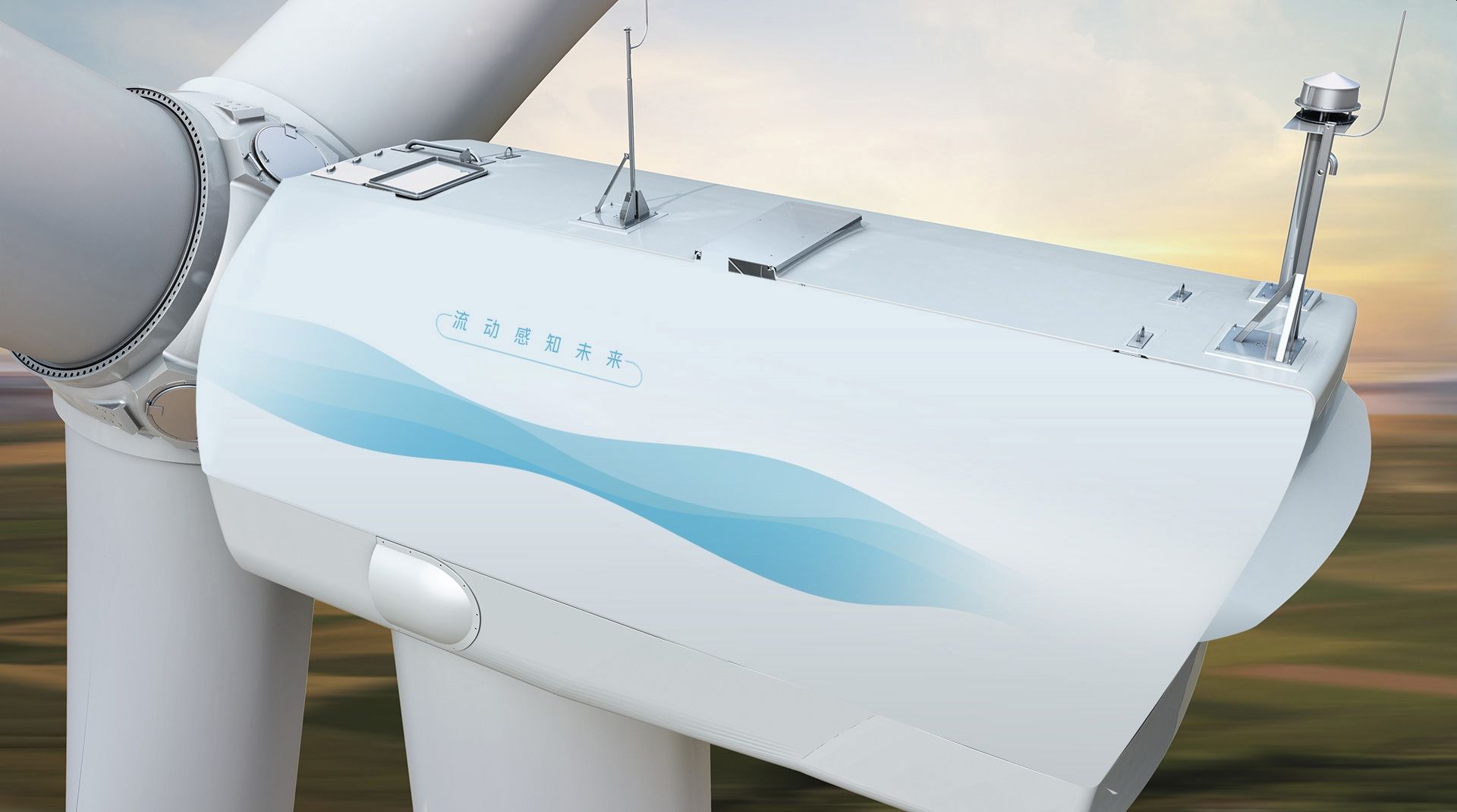

Possible applications of the innovative oil sensor systems WearSens WS 3000 and GreaSens GS 3000 on wind turbines.