GC / Trace gas analysis

Discover our broad product portfolio of analytical measurement technology for gases and fluids:

Gas generators, oil sensors, trace moisture measurement in gases, trace gas analysers

LDetek HyDetek System – Integrated gas chromatograph system for hydrogen purity

An all-in-one device for the measurement of trace impurities (ppb/ppm) N2-Ar-He-O2-CH4-CO-CO2- NMHC-sulphur-formaldehyde-ammonia-halogenated formic acid and water in hydrogen. The device is able to fulfil the ultra-high purity requirements for hydrogen used in fuel cells according to ISO 14687.

The HyDetek system utilises a combination of LDetek's plasma emission detector, thermal conductivity detector and a quartz crystal moisture sensor to measure all critical impurities. It is suitable for use in electrolysis plants for the production of green hydrogen as well as for steam methane reforming processes and grey hydrogen.

Certifications

- CE in accordance with the EMC Directive 2004/108/EC, EN 61000-6-2:2005 for immunity & EN 61000-6-4:2007 for emissions

IECEx : Ex pxb IIB+H2 T4 Gb (with MultiDetek Ex solution) - ATEX : II 2 G Ex pxb IIB+H2 T4 Gb (with Multidetek-Ex solution)

- Meets UHP requirements for hydrogen in fuel cells in accordance with

ISO 14687 - Multiple detectors: PED, TCD and quartz crystal are available on request

- Integrated ultra-high purity sample stream selector system (remote controlled)

Online N2 Spurengasanalysator for Argon, Helium, Crude Argon and other Noble Gases: LD8001

The LD8001 is an online analyser for monitoring N2 traces in Ar/He/Crude Argon. A plasma emission detector is used to selectively measure traces of N2 in pure argon or/and helium crude gases as well as in argon with up to 5 % O2. The analysis of N2 traces in neon, xenon and krypton can also be realised.

The LD8001 has been updated with a modern, digital design, but still serves the same applications as the LD8000. It offers a smarter and more seamless user experience while retaining its ability to accurately detect nitrogen impurities in argon, helium, raw argon and other noble gases.

Gas analyser for impurities in Helium and Argon LD8001 MultiGas

The LD8001 MultiGas is an online gas analyser for monitoring traces of N2, O2, H2O, CnHm in helium. The compact 4U device was developed to fulfil the requirements of helium cryogenic systems for online measurement. The LD8001 MultiGas has been updated with a modern, digital design, but still fulfils the same purpose as the LD8000MG. It provides a smarter and more seamless user experience while still being able to monitor trace levels of nitrogen, oxygen, moisture and hydrocarbons in helium and Argo.

Features

- Compact rack-mounted housing (3U) to cover up to four measurements (N2, O2, H2O, CnHm)

- Integrated bootloader for software update via Ethernet

- Ultra-high purity electronic flow controllers for sample flow control

- Large measuring scale

- 5.6'' LCD touchscreen

- 4-20 mA outputs

- Range identification & alarm status & calibration contacts

- Alarm history

- LAN/Web control

- Low sample consumption

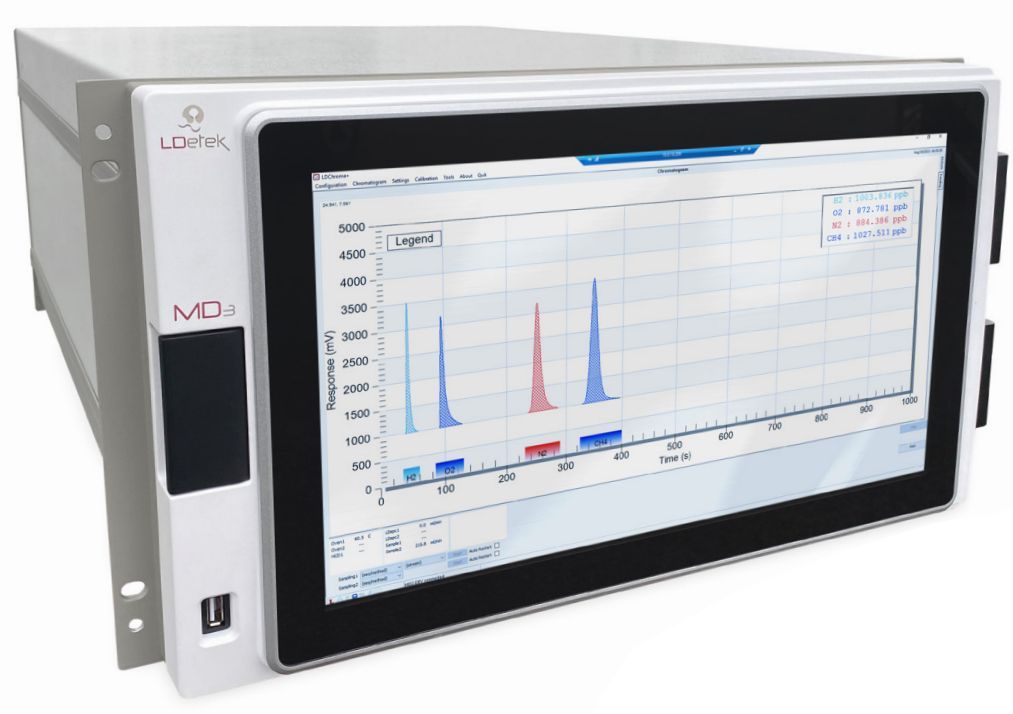

Modular Process-GC: MultiDetek3

The MultiDetek3: your ultimate solution for industrial gas chromatography, customised to your process. The innovative MD3 offers a wealth of features, a wide range of state-of-the-art detectors, including PED, TCD or FID.

The MultiDetek3 is the latest development in our popular range of compact industrial gas chromatographs. It is more than a simple gas chromatograph:

It is a modular process GC instrument that combines the functionality of two GCs in one and also offers the ability to monitor trace levels of moisture and oxygen online. The device has been completely redesigned and features an extra-large 15.6-inch touchscreen for easy visibility and operation. It has a dual sample inlet and online modules that allow simultaneous analysis of trace moisture and oxygen as well as trace contaminants. The device is temperature controlled to improve stability and performance. The software interface is our latest LDChroma+, which provides a more sophisticated data management and planning platform.

All this allows you to control your process with the highest precision and reliability, increasing the efficiency of your plant.

Features:

- Convenient and flexible configuration

-Choose between PED, TCD or FID detectors

-2 sample inlets allow simultaneous analysis of two gas streams

-Built-in online sensors for trace moisture and oxygen analysis - Modular design for easy maintenance

- Simple operation with 15.6" colour touchscreen

- Temperature controlled to ensure maximum accuracy and stability

- Sophisticated data management with dedicated software

Automatic gas dilution system LDGDSA

For the multi-point calibration of gas analysers

The LDGDSA is a user-friendly gas dilution system that offers flexibility in the automatic generation of the desired gas mixtures. The Windows user interface provides the ability to control and monitor the mixtures, flows, pressures and concentrations remotely.

The system can store multiple gas cylinders, making it easy to select the right cylinder for creating different mixtures. This reduces costs compared to needing a specific standard for each mixture required. The dilution system is equipped with an automatic pressure regulator installed on the zero gas line, on the span gas line and to regulate the outlet pressure of the mixed gas line. This improves the stability and regularity of the flow controls. Each flow table uses a 10-point calibration curve to characterise the linearity of each flow controller.

Features:

- Automatic calculation of dilution concentrations

- Automatic pressure control

- Wide range of dilution ratios (up to 1000 to 1)

- Windows user interface via serial communication

- Several standard gas libraries available

- Alarm system

- 3U cabinet

- Integrated heated gas purifier to generate an ultra-high purity zero gas reference (optional)

Would you like to find out more?